Recent Projects

WDC Garrymere Water Treatment Plant

A new containerised water treatment plant was built at Garrymere for the Waimakariri District Council. The contract included the installation of four new 30m3 water reservoirs and an upgrade of the existing chlorine dosing system.

The treatment plant included two stages of cartridge filtration, chlorine dosing as well as UV disinfection.

The work was all carried out by G&T Construction staff apart from the chlorine system upgrade which was sub contracted to Filtec.

CWTP Channel Repairs

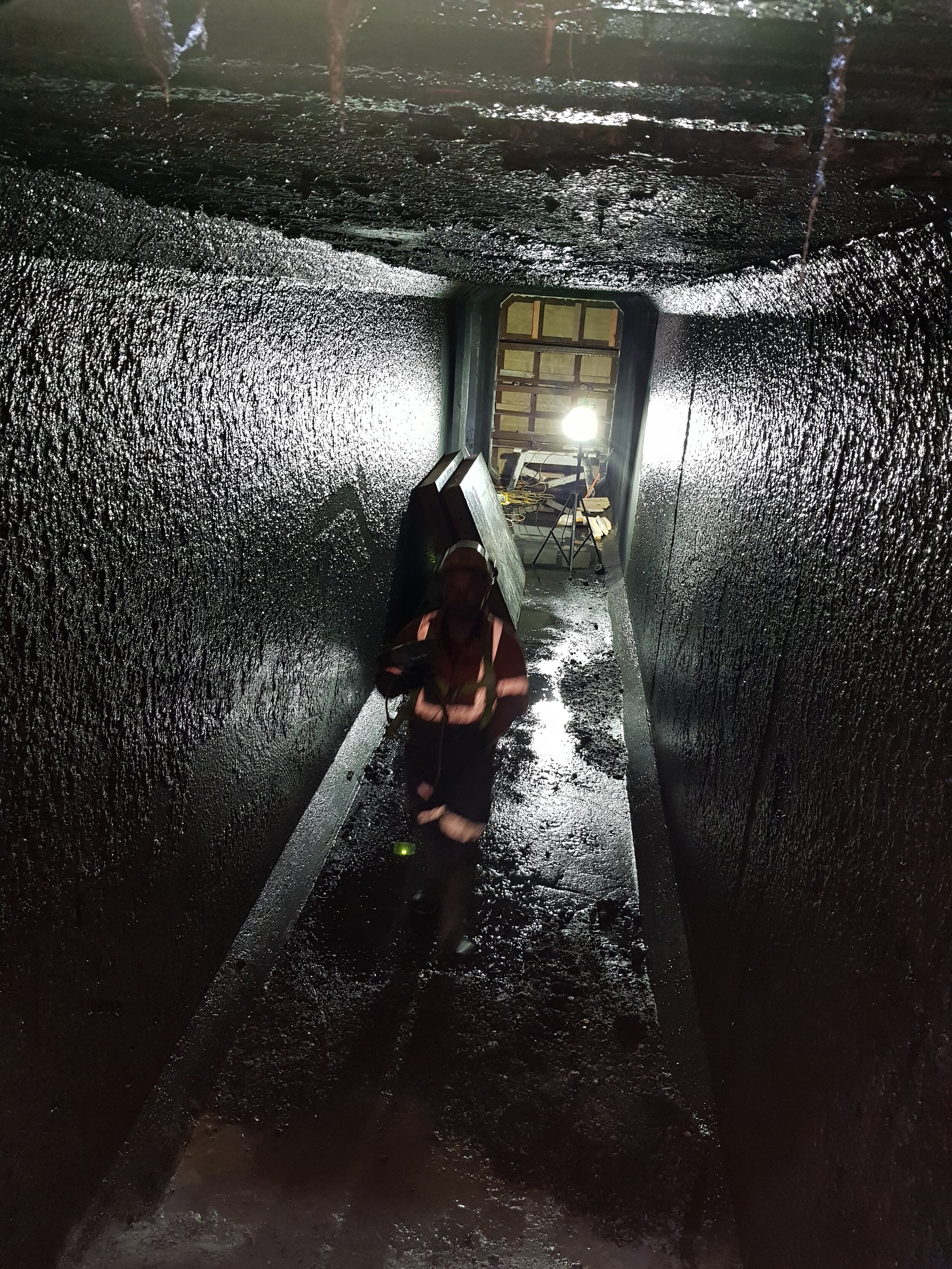

As part of the on going maintenance at the Christchurch Wastewater Treatment Plant, G & T Construction have been awarded a contract to carry out repairs to existing plant channels, many of which have not had any maintenance since they were constructed in 1957.

The repair work involves the removal and reinstatement of the concrete channel roof complete with HDPE liner and the construction of new HDPE lined concrete walls down below the operating level of the channel.

As these channels are all in service and often there is no alternate route for the plant effluent, a new bypass channel was constructed to allow flows to be diverted around the work site.

WDC Kaiapoi WWTP sludge removal

The oxidation ponds at Kaiapoi had some areas of high sludge build up & G & T Construction were contracted to remove this sludge from the ponds and pump it to on site dewatering bags.

The sludge was removed using our hydraulic powered Dragflow HY85 sludge pump mounted on one of our 35 tonne excavators. The sludge was mixed with a flocculant before being discharged into a large dewatering bag.

Approximately 1,800m3 of sludge was removed over a 10 day period.

CWTP Sludge Lagoon remediation

We recently completed a project to decommission two sludge lagoons at CWTP that had suffered extensive damage in the 2011 Christchurch Earthquakes.

The lagoons were part of the original Waste Water Treatment Plant at Bromley and date back to the early 1900’s. One lagoon had a mixing tank built in it in 2005 and the other was used for vacuum tanker waste dewatering during the earthquake rebuild.

The dividing wall between the sludge lagoons and the sludge mixing tank were demolished and the waste material was crushed for re use as backfill on site.

One lagoon is to be filled to ground level for a future biogas installation and other other lagoon is to retained for emergency discharge of digested sludge. The digested sludge storage lagoon required a new reinforced concrete water tight cell to be built as part of the contract scope.

WDC Wellhead Improvements

As part of the nation wide improvement program to drinking water supplies, G&T were contracted by the Waimakariri District Council carry out maintenance and upgrade work on various well sites in Kaiapoi & Woodend.

The work included bentonite grouting of the well casings, sealing of wellhead chambers and replacement of pipe work and fittings as required.

WDC Rangiora WWTP

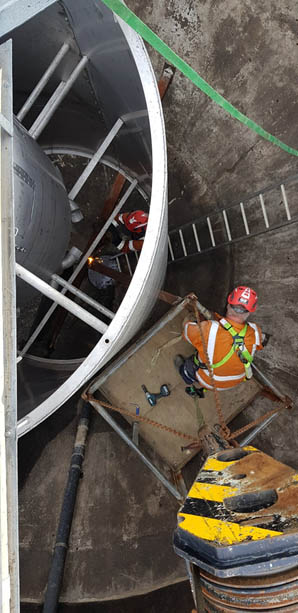

We recently completed the construction of a new inlet works pumping station, screenings channel and grit removal plant for the Waimakariri District Council at Rangiora.

The job included a sheet piled and dewatered 8mtr deep pumping station, a raised screen channel structure and various supporting structures.

All mechanical fabrication and fit out was completed by our own staff. This included the fabrication and installation of walkways and stairways, installation of penstocks and stop boards as well as installation of the screens and grit removal equipment.

CWTP Grit Tanks

The recent Christchurch Earthquakes prompted a contract to improve the sand and grit handling capacity of the main CWTP Grit Tanks.

The contract involved linking the Grit Tanks so that any tank could be connected to any of the Primary Sedimentation tanks. Separation of the grit pumping to each tank was included as well as the provision of a new grit washer and installation of grit concentrators to all three grit washers.

Later in the contract the first stage of Channel Repairs was added the our work scope to as much of the work used the same isolations as required for the Grit Tank work. The Channel Repair work involved many complex shutdowns and flow diversions within the Treatment Plant to ensure minimal disruption occurred to the treatment process. Once again HDPE protective linings were installed on the face of the new concrete work.

WDC Kaiapoi Second Screen

As part of our work at Rangiora WWTP, a step screen was removed and this was relocated to the Kaiapoi WWTP. We built a new reinforced concrete screen structure adjacent to the existing structure. The concrete work included installation of a HDPE liner.

The tie in of the new screen channel to the existing sewer network required over pumping of all the Kaiapoi sewer flows for a period of 10 days.

WDC Oxford WWTP Aeration

We recently completed the fabrication and installation of an aeration system at the Oxford WWTP. G&T worked both for the Waimakariri District Council to install the aeration feed pipe work and blowers and subsequently for the aeration equipment supplier Xylem.

The Xylem work included the fabrication of all the stainless steel components for the aeration system as well as on site installation and commissioning.

Concurrent with the installation of the aeration grids, extensive modifications were carried out to the existing wastewater tanks on site during a 3 day shutdown of the plant.

CCC Northern Relief Sewer

As part of the SCIRT rebuild following the ChCh Earthquakes, G & T Construction repaired as section of the Northern Relief Sewer on the corner of Hills Rd & Dudley St.

The work involved sheet piling around the existing damaged live sewer pipe and installing a bypass so that the damaged section could be replaced.

The new pipe work was GRP supplied by Maskell Productions who operate out of the G & T Construction Kaiapoi yard. The pipe sections were site measured and final fabrication carried out in our work shop.

NZ Salmon Tentburn

G & T Construction returned to NZ King Salmon at Tentburn in July 2018 to install a steel capping over the pile connections we had previously installed, to prevent erosion by wave action and beach gravel.

We also poured a new layer of reinforced concrete over sections of the outlet culvert that have been eroded over time. Steel plates covering previous storm damage were also removed and new concrete poured over the openings.

CCC PS15 Piling

G & T Construction were sub contracted to HiWay Stabilisers to install steel piles inside drilled cement stabilised piles as part of the SCIRT rebuild of Pump Station 15.

The 24mtr long piles were installed using our crane suspended vibro hammer into the pile drilled by HiWay Stabilisers. The pile installation had to closely co ordinated with the HiWay Stabilisers site staff as there was only a short period when the steel pile could be installed before the cement pile set up.

EQ Memorial Wall Sheet Piling

G&T Construction installed a mixture of permanent and temporary steel sheet piling for this contract as well as permanent PVC sheet piles to the river edge.

The permanent steel sheet piling was installed immediately behind the memorial wall and was left in place to ensure support of the road behind the wall.

Temporary sheet piling was installed to form access ramps for the construction crew.

The river edge in front of the memorial wall was secured using permanent PVC sheet piles. G&T fabricated a driving mandrel for these sheets in our workshop and this enabled the flexible sheets to be installed without damage to the PVC sheets.

CWTP Gas Engine Replacement

This contract involved the provision of mechanical services for the replacement of two existing gas engines with a new more powerful engine.

The work included fabrication and installation of gas pipework, cooling water and exhaust connections and fabrication and installation of inlet and exhaust air ducting and supports.

CWTP Trickling Filter Repairs

The existing Trickling Filters at CWTP sustained damage during the ChCh earthquakes and required seismic strengthening to secure them for the future.

The two 52mtr diameter concrete tanks needed a reinforced concrete strengthening band to positively connect the precast wall panels to tank floor & foundations. Concurrent with the new concrete beam, G&T staff installed a new GRP air duct around the tank perimeter.

The internal tank mechanism was also removed for refurbishment. This work was carried out by G&T staff in conjunction wit the CWTP maintenance team.

The internal tank mechanism was also removed for refurbishment. This work was carried out by G&T staff in conjunction wit the CWTP maintenance team.

The existing concrete outlet pipes for each filter tank were also replaced with new HDPE pipe work.

Whilst the tanks were out of service, inspections were carried out of the underfloor areas which revealed further earthquake damage. The existing concrete work was repaired and a protective coating applied as required.